Do you know how the weather will shake out this spring? We don’t either, but numerous research studies have shown average U.S. corn yields increase with the addition of a starter fertilizer. Here in the Midwest we are very used to seeing all four seasons in one week, sometimes in one day– as an insurance policy against all of the elements, starter fertilizer is a great addition to your spring plan. So what does starter fertilizer provide?

In this blog, we’ll learn about the importance of starter fertilizers by understanding starter basics, when to use starter fertilizer, and what to consider while using starters.

Understanding Starter Fertilizers

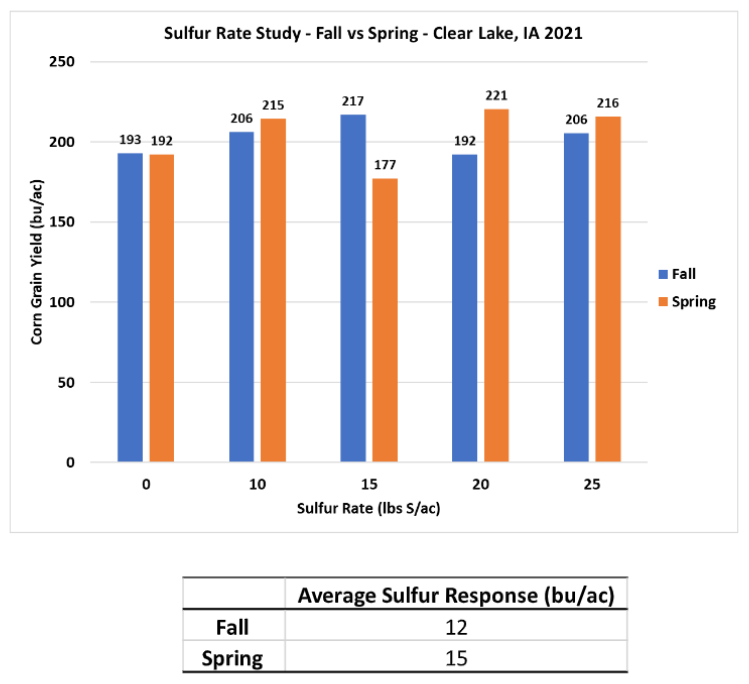

Starter fertilizer is a combination of nutrients applied to the crop at or around planting. Depending on the placement of the starter fertilizer, the nutrient application consists of phosphorus, potassium, sulfur, nitrogen and zinc. Starter fertilizer can be especially helpful in environments such as:

- no-till or reduced-till soil

- sandy soil

- cool soil

- soil with low organic matter

- soil with low P, K & other soil minerals

As we continue to plant earlier in April, these soils are oftentimes colder than the crop needs for adequate nutrient uptake. Soil nutrients are slow to mineralize in cold soils, and starter fertilizers offer crops nutrients that may not be readily available in the soil during times of unseasonably cold weather or exceptionally early planting where nutrient movement and absorption is noticeably slower. By using a starter fertilizer early in the growth cycle, you can help ensure proper root development—which is essential for successful yields. Why? Because corn has little, itty-bitty roots that can’t always reach the nutrients present in the soil. By using starter fertilizer and placing it close to those roots, it helps the crop out while it is young. Kind of like a hearty breakfast early on can jumpstart your day, a strong starter fertilizer early on can jumpstart your corn crop! Even for well-producing fields, starter fertilizer can be advantageous for yields and as Dr. Jake states, “a cheap insurance policy” to hear what else Dr. Jake says about starter fertilizer check out this liqui-grow loop: https://youtu.be/yuRvWZ27oi4?si=F9DIc8Fvvgo1sr8r

Why Starter Fertilizers?

Root Development

After germination, corn kernels develop two root systems. The first set of roots developed are seminal roots, followed by nodal roots crucial for nutrient uptake. If nodal roots face stress, it can hinder nutrient absorption and overall plant growth. And when a plant’s health falls behind by two or more growth stages, it becomes very difficult for that plant to catch up, therefore hurting overall yields.

Rented Land Fertility

According to Iowa State University, about 60% of crop ground is rented land. While we know it’s possible to build soil fertility over time, short term leases can pose a risk for renting low-fertility fields, as tenants might not take as good of care of the farm as long term leases. This is another instance where starter fertilizer can bridge that gap, providing necessary nutrients for a relatively low cost with a more immediate return on investment. A great way to be aware of your soil fertility is through soil sampling– check out our last blog to learn more on soil sampling!

Starter Fertilizer Considerations

The goal of any fertilizer is to feed the crop and the yield. That being said, we always want to be conscious of seed injury. When talking about starter fertilizer, we specifically want to be aware of salt injury which means some nutrients have higher salt contents and if they come in contact with your seed corn, they will injure or kill the seed. It’s very important to know what products you are using and what placement you have available on your planter. Never hold this information back when working with an ag retailer, we don’t want to give you the wrong information because we didn’t know all the pieces to the puzzle.

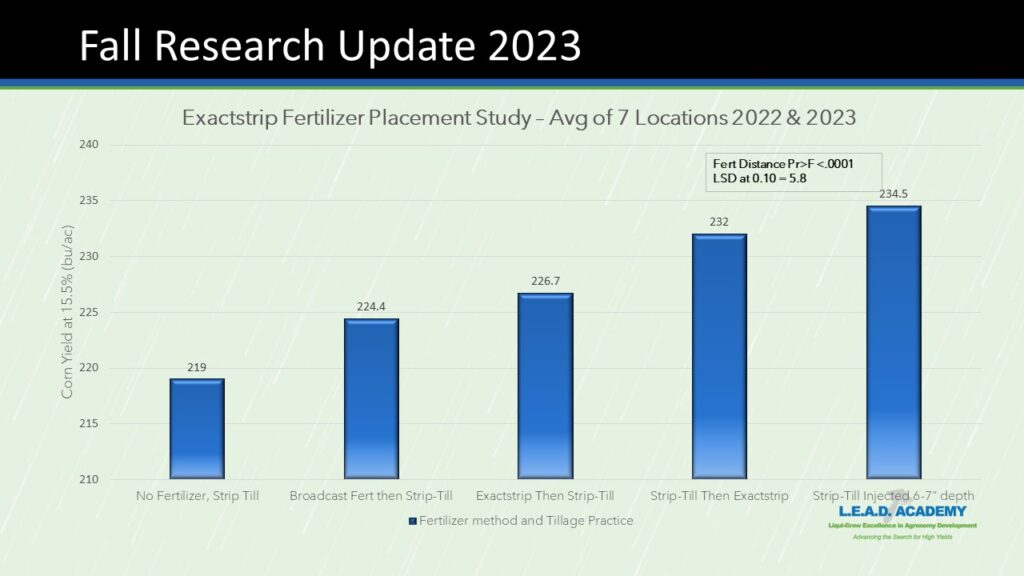

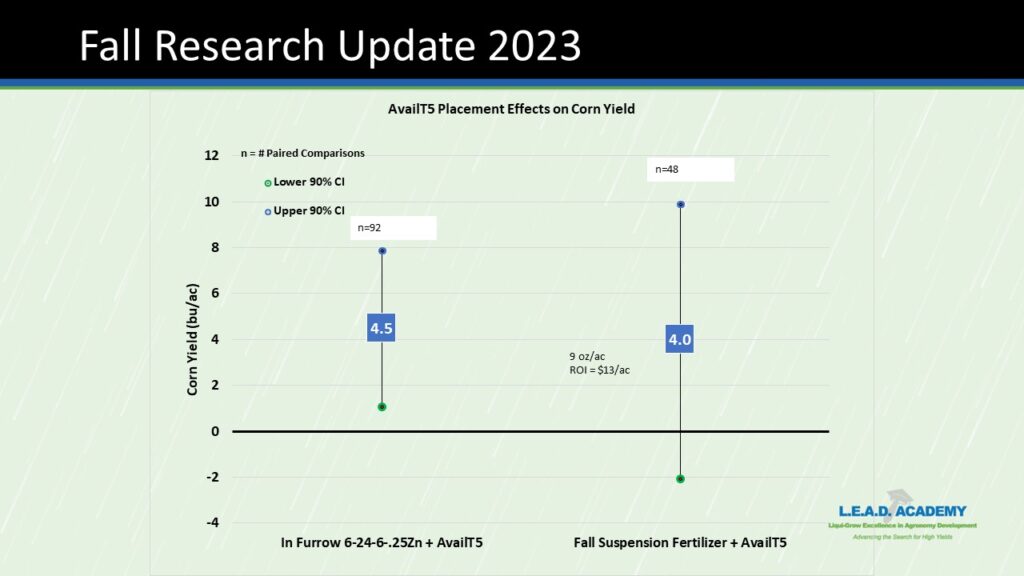

6-24-6-.25 (Zn)

6-24-6-.25 (Zn) is a seed-safe in-furrow starter fertilizer with low salt content. With the recommended three to six gallon per acre application, salt injury is uncommon. As Dr. Jake says, this is the “crown jewel of starters and an extremely successful product of Liqui-Grow.”

4-10-10

For fields with significantly low phosphorus and potassium levels, 4-10-10 is another quality starter fertilizer option. This is an out-of-furrow fertilizer, allowing higher application rates without seed injury in the 10 to 20 gallon per acre range. Choosing a starter fertilizer can have many considerations, including soil health and even efficiency preferences—higher application rates will mean more stops to fill up.

18-3-3-3-.15 (Zn)

Another option to consider, especially for high phosphorus and potassium soils, is our 18-3-3-3-.15(Zn). This is a complete N, P, K, S, and Zn starter. Our 18-3-3-3 is an out-of-furrow fertilizer with application rates in the 15-30 gallon per acre range. This is a great option for continuous corn since it provides a readily available source of nitrogen, when we commonly see N tied up in residue.

Talk to your Liqui-Grow sales applicators to learn more about which starter fertilizer is right for you.

To Conclude

Starter fertilizers can positively impact corn yields, especially in specific geographical regions or under certain soil conditions. In essence, starter fertilizers are like a booster shot for young corn, providing the plants with the nutrients they need to thrive during the critical early stages of growth.

Questions? Give us a shout!

Text us at 564-220-2508 or email questions@liqui-grow.com.